Dillygence

Decarbonization through flow efficiency: ROI without CAPEX

Simulation flux de production : refusez le pilotage à vue, exposez les goulots cachés et garantissez la rentabilité long terme de vos usines.

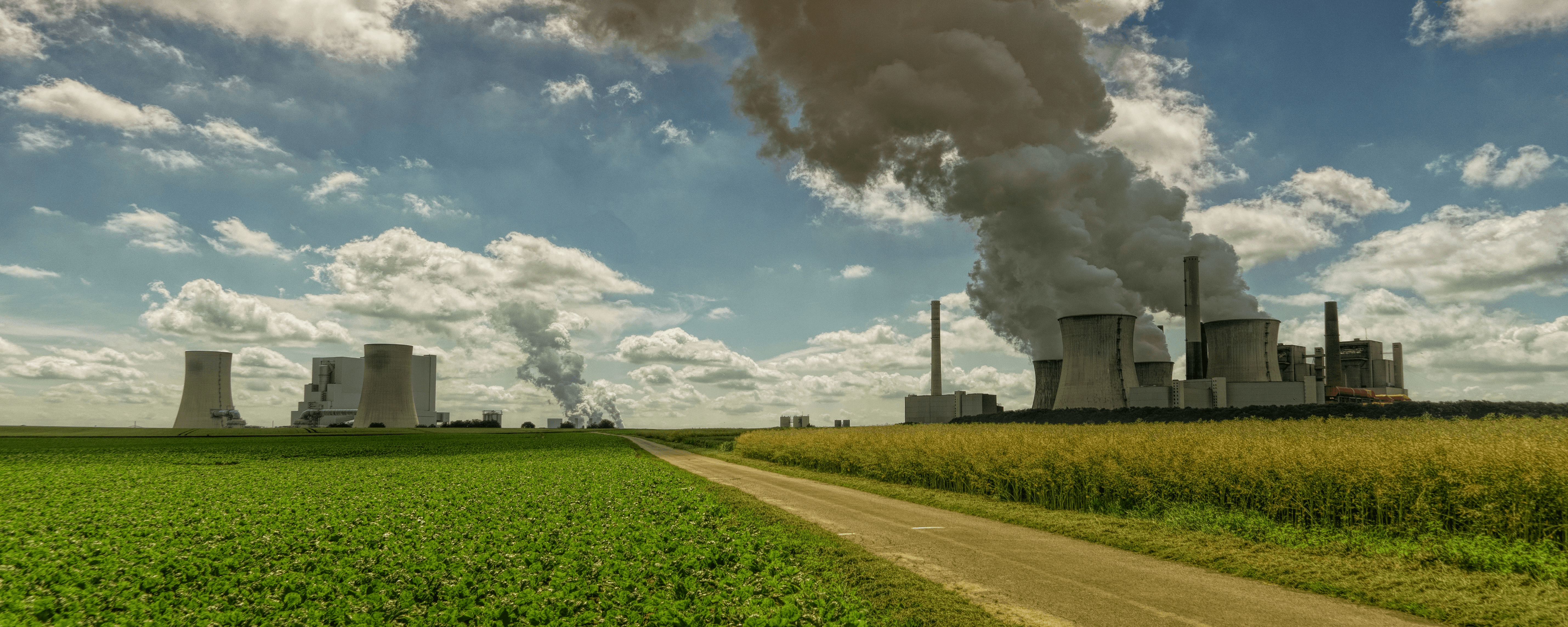

Introduction: Decarbonation, a pillar of industrial competitiveness

Decarbonation in industry requires a comprehensive transformation that goes beyond simply switching energy sources or adopting green technologies. The challenge: turning a constraint into a lever for competitiveness, by optimizing both economic and operational performance. This means rethinking the organization, adjusting resource management, and synchronizing production flows, rather than stacking isolated technical solutions. Energy performance is built on mastering, stabilizing, and optimizing flows, thus limiting energy demand. Any decarbonation strategy must integrate coherence between processes, resources, and flows. The CSRD enforces increased transparency on consumption and emissions, revealing inconsistencies in value chains and driving deep transformation. For decision-makers, this is an opportunity to align performance, sustainability, and operational excellence.

I. CSRD: Revealer and Accelerator of Transformation in Industry

Moving from Compliance to an Active Organizational Strategy

Reducing CSRD to a compliance matter deprives the company of a competitiveness lever. An active reading of the CSRD identifies structural weaknesses responsible for energy overconsumption. It acts as a compass to target breaks in industrial flows and correct organizational dysfunctions that create unnecessary stock and slow operations. Used as an optimization tool, regulatory compliance paves the way for sustainable gains and increased transparency.

Leveraging Weaknesses Revealed to Boost Performance

Careful analysis of the gaps highlighted by CSRD enables building a solid industrial strategy. Reports highlight organizational waste: waiting times, movements, shutdowns, or restarts. Most of the energy consumed compensates for flaws in flow management. Action must therefore focus on synchronizing processes, reorganizing workshops, and reducing work-in-progress. Decarbonation becomes a tool for continuous improvement, generating immediate savings and a lasting reduction in carbon footprint.

Why Classic Energy Solutions Are No Longer Enough?

Traditional approaches, focused on CAPEX investments, quickly reach their limits if not paired with flow optimization. Investing in renewables or improving insulation does not solve internal disorganization. The root cause of overconsumption is organizational. Only a systemic approach, reducing energy demand upstream, can deliver effective and lasting decarbonation.

II. Reducing Organizational Waste: The True Lever Against Overconsumption

Industrial Process: How to Distinguish Useful Consumption from Waste?

There is often confusion between energy consumed to create value and energy absorbed by dysfunctions. Ideally, the industrial process maximizes time and energy devoted to added value. Yet, a significant portion of energy compensates for planning defects and downtime. Distinguishing technical necessity from lack of synchronization or poor design is crucial. Mapping flows and measuring waiting times become priorities to effectively target energy savings.

Idle Machines, Oversized Logistics, Unstable Production Batches: The Hidden Causes

Many pieces of equipment remain powered during idle periods, internal logistics are often excessive, and production batches are unstable. Idle machines, unproductive movements, batch variations, and restarts cause consumption spikes. Better synchronizing flows and reducing intermediate stocks lowers energy and operating costs.

Desynchronized Flows: Direct Impact on Energy Performance

Desynchronized flows lengthen production cycles, lead to longer lead times, and spread out energy consumption. Rigorous synchronization of flows can reduce energy consumption by 10 to 25% without additional investment. Decarbonation becomes a direct result of organizational mastery.

III. Lean Flows and Energy Sobriety: A Winning Model

Reducing Lead Time: The Key to Controlled Consumption

Reducing lead time focuses energy on real value creation. Less idling, less waiting, fewer restarts: energy is used more efficiently. Studies show that lowering lead time can decrease energy consumption by 10 to 25% without changing equipment. Managing lean flows is the first step in a high-performance decarbonation strategy.

Optimizing OEE: Focusing Energy on Value Creation

High OEE reduces the share of energy dedicated to non-productive activities. By analyzing losses (stoppages, slowdowns, quality defects), they are corrected through better flow organization and rigorous planning. Result: fewer kWh per unit produced and a reduced carbon footprint. Mastering OEE is central to combining industrial performance and decarbonation commitment.

Smoothing Loads: Limiting Energy Peaks

Load variations generate overconsumption and thermal losses. Adapted planning, dynamic stock management, and synchronized supply allow these peaks to be smoothed. Result: reduced peak energy needs and tangible reduction in carbon footprint.

IV. Rethinking Industrial Design to Maximize Energy Savings

Incremental Optimization or Radical Overhaul: Which Choice for Decarbonation?

Progressive optimization quickly reaches its limits, often 5 to 10% improvement. Only a complete overhaul of the system—reengineering flows, new layouts, advanced synchronization—achieves a 20 to 30% reduction in energy consumption. The key: dare to challenge the status quo and favor an integrated vision based on real breaking points.

Industrial Design: The Foundation for Sustainable Energy Performance

Industrial design determines energy efficiency. Equipment placement, flow structuring, and technological choices shape energy demand in the long term. An industrial design focused on fluidity, synchronization, and eliminating unnecessary movements guarantees efficiency levels unattainable through simple later adjustments. Using a digital twin anticipates blockages, optimizes scenarios, and manages the industrial lifecycle.

Concrete Cases: Flow Synchronization and Layout Reorganization

Experiences converge: synchronizing flows and transforming layouts significantly reduce energy consumption. Rethinking a factory with lean flows, eliminating logistic loops, real-time management, and reducing stocks enables a 20 to 30% drop in consumption. Flow optimization and smart space organization are the pillars of value-creating decarbonation.

V. Building a Sustainable and High-Performance Decarbonation Strategy

Stabilizing Flows: A Prerequisite for Reducing Energy Demand

Before investing in renewables, flows must be stabilized. A stable organization maximizes equipment use, reduces waiting times, and eliminates consumption peaks. This mechanical reduction in energy demand is the basis for any energy optimization or substitution.

Prioritizing Operational Optimization Before Energy Diversification

Multiplying alternative energy sources does not eliminate an inefficient organization. As long as flows remain unstable, investments only mask internal weaknesses. The logical order: stabilize flows, structurally reduce demand, then invest in decarbonating residual energy. Energy performance reflects organizational maturity and operational excellence.

Operational Excellence: The Foundation of a Decarbonized and Competitive Industry

Operational excellence is the most effective path to decarbonation. Managing a stable, synchronized, and optimized industrial system creates the foundation for reducing carbon footprint. Mastery of fundamentals, development of internal skills, investments in industrial design, and advanced simulation tools ensure profitability, sustainability, and responsibility for the industry of tomorrow.

The cheapest kWh is never the one you produce differently or via a new technology, but the one your organization no longer requires thanks to the elimination of waste, flow optimization, and sustainable reduction of energy demand at the source. Rethinking resource management, synchronizing processes, and eliminating downtime are concrete levers to reduce consumption. Every coherent organizational action directly and measurably lowers the carbon footprint, while strengthening industrial performance and competitiveness.